Overcoming Challenges in the Livestock and Fisheries Industry with Technology

Chickin, Pitik, DELOS and FisTx approaches in developing IoT solutions and introducing them to farmers

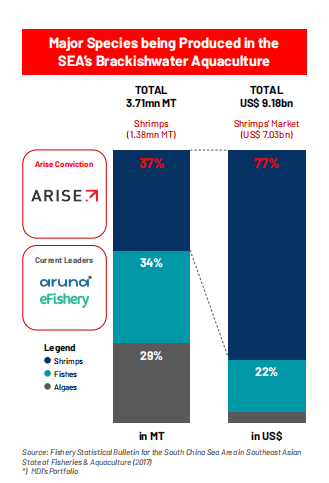

Need time eight years for e-Fishery proves that the aquaculture industry is “the sleeping giant” through a series C fundraising that is participated by big-name investors. Aquaculture production in Indonesia is still the third in the world after China and India. In 2018, aquaculture production reached 5,4 million tonnes worth $11,9 billion (FAO 2020).

Not only aquaculture, livestock also has great potential. Consumption of chicken meat in Indonesia in 2020 will reach 7,9 kg per capita or around 3,5 million kg per year. It is estimated that in 2029, chicken consumption will continue to increase to 9,32 kilograms per capita. Nevertheless, according to OECD-FAO, the consumption of chicken and beef by the people of Indonesia is still low compared to neighboring countries. Per capita consumption of chicken only touched 11,6 kilograms, while beef was lower at 2,7 kilograms.

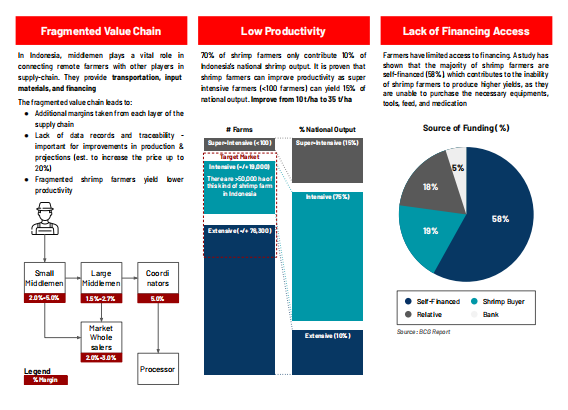

In addition, the industry is still plagued by a number of classic issues. Starting from access to capital and production inputs, production problems (such as feed inefficiency, disease, seed quality and cultivation technology), and post-production problems (such as low farm prices due to long supply chains). Additional issues, such as inappropriate infrastructure and policies, also pose challenges.

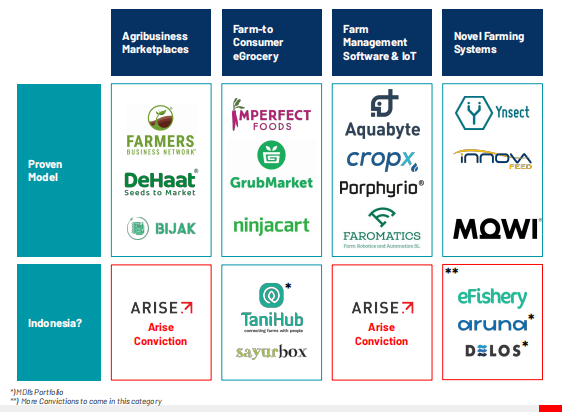

However, animal cultivation remains an attractive sector, as demand for animal protein increases and many startups try to solve the various problems that exist in each segment. The founders of this startup come from multi-disciplines, not only from the aquaculture or poultry sector. They are Chickin Indonesia, Fistx, Delos, and Pitik.

Together DailySocial.id, they shared their views on why innovation in this sector tends to be slow in Indonesia and how to solve these challenges with technology.

Co-founder and CEO Indonesian Chickins Tubagus Syailendra Wangsadisastra said, Digital innovation in this sector is slow because the supply chain landscape is still fragmented and there are many middlemen which means there is no data transparency. This drives a mismatch between demand and stock availability.

Innovation in this segment is slow, because it interacts with farmers and breeders who are generally not yet adaptive.

"From the side market adoption, not yet as massive as in other industries. Wavehis recently will be emery industry in the future. I'm sure this will be big after going through certain phases. The e-commerce and fintech phase is over. People in tier "3 and 4 already use technology, then we can easily enter cultivation," said Tubagus.

Delos CEO Guntur Mallarangeng added from another perspective. He explained that the answer is actually simple but complicated. Simple, because not many farmers have the financial capacity to invest in cultivation technology or technical understanding of cultivation technology, so they end up being left behind by farmers in other countries.

The complicated answer relates to systemic problems that need to be looked at at a macro level. They are the lack of development and application of aquaculture science in Indonesia, lack of financial inclusion, lack of adoption of the latest technology, and growing expertise and expertise in the fishing industry.

"The combination of the 4 points above are the factors that influence the lack of progress in our aquaculture industry. Lack of financialinclusion "from financial institutions in our country contributes to the lack of investment that can be obtained by the aquaculture industry, thus making the price of innovation, even long-term investment, unaffordable," said Guntur.

He continued, “This lack of investment makes the training and development of experts very slow, even insufficient for industry development targets. "The lack of expertise and investment makes research, scientific development and application, and technology adoption difficult to accelerate."

Combine IoT with other technologies

Based on these challenges, the IoT approach combined with other technologies is the first step to introduce the digital world in this segment. Examples of companies that focus on IoT-based sensors and devices to check water parameters quickly and precisely are Jala, FisTx, Delos, and eFishery. Apart from that, there are also those that focus on water treatment such as NanoBubble, Venambak, and Banoo which provide machines to optimize dissolved oxygen (DO).

With this device, water quality parameters can be presented sequentially real-time or as a data series, making it possible to predict water quality more precisely and take action if there are unusual trends. This breakthrough makes fish and shrimp farming more predictable and easy to practice for beginners. This also makes the aquaculture sector more attractive to young people.

However, according to FisTx COO Rico Wibisono, the most challenging thing in providing water quality inspection tools, apart from ensuring fast and accurate data, is how to provide appropriate advice to farmers about what steps to take based on the measurement results. He said that collecting water quality data is one thing, but using the data properly is another.

FisTx developed special technology for shrimp cultivation that focuses on a more sustainable water improvement process. The example is mobile water sterilizer with environmentally friendly disinfection technology and supported by ultraviolet light without residue. This technology, when compared to chemicals, can make disinfectant costs between 35-53% more efficient.

"Then we also developed technology for feed additives to increase industrial absorption, so that growth is faster and there is less waste. All of this technology is directed at sustainability and farmer welfare.”

Tubagus added, for all cultivators, data is the most important issue in overcoming their problems. Utilizing accurate data can help with evaluations to prevent crop failure and can predict what harvest results can be produced.

To answer these needs, Chickin offers IoT and SaaS devices to collect data and matchmaking what data is in the cage for B2B business needs.

They did matchmaking data on chicken demand, size, price, grade and matched with existing data in the breeder's cage. IoT devices are used to increase farmer productivity by reducing FCR feed costs (feed coverage ratio). The success of the harvest is determined by how much feed is converted into meat optimally so that energy is not wasted.

Chickin provides an IoT-based integrated intelligent farm management system solution through the Chickin App – Micro Climate Controller (MCC) and Chickin Smart Farm which is expected to reduce FCR numbers thereby resulting in better feed efficiency. With IoT-based farm management and AI support, Chickin makes it easier for breeders to cultivate optimally, productively and efficiently.

They no longer need to worry about weather conditions in the cage because the temperature and humidity can be adjusted manually via the Chickin App connected to their smartphone. The existence of IoT and AI support makes it possible to carry out remote cultivation because the control process is easier, while also maximizing production efficiency and quality with low mortality rates.

"We can use AI data to adjust the chicken's temperature needs, because cost feed is expensive. "IoT is for controlling the temperature needs of chickens, what temperature, humidity, so that partners can get optimal results in terms of income," explained Tubagus.

In creating this solution, he admitted that he had carried out scientific research for years, while carrying out experimental tests in several cages in Central Kalimantan and Central Java. "The equipment is simple to make, add a sensor to know the temperature in the cage and AI logic for the temperature requirements of a chicken. But what takes a long time is the success of the process, how far the percentage reduces feed and electricity costs. Once we have solid data, we can produce even faster."

Approach in the field

In the midst of inadequate literacy in all corners, the process of introducing it to farmers has its own challenges. Tubagus explained that actually the breeders already understand the concept climate control. The target users of this product are farmers Full house who already has a fan, blowersand cooling pad.

Thus, from Chickin's side, it only provides updates to the temptron device in the cage with the temperature sensor for the chickens in the cage real-time. Even so, the company still has a field team and consultants who can help farmers when operating the equipment.

Co-founder and CEO Pitik Arief Witjaksono added, in introducing Pitik's solution, his party regularly holds training both online and offline. In collaboration with the Edufarmers Foundation, a non-profit organization from Japfa, they introduced the Pitik application in East Java.

“Our technology has been proven to help farmers [Kawan Pitik] reduce chicken mortality rates by 50% and increase feed use by more than 12%. "So far their response has been positive in using technology from Pitik," he explained.

In particular, the company provides comprehensive support to all farmer partners in supplying the best quality sapronak (livestock production inputs). “Pitik provides the technology farm management so that farmers can carry out the production process more efficiently, and take all production results at competitive prices. We do all of this with a transparent contract scheme so that we can be the best breeder partner."

Meanwhile, FisTx sees that the education process for farmers is very dependent on the psychology and psychographics of where they are. For a completely new location, the first thing a company does is search early adopting and continue to monitor it until there are satisfactory results. From there, hope emerged domino effect, marked by word-to-mouth branding. "Thank God, up to now we have more than 340 fish farmers spread across 21 provinces," said Rico.

The FisTx business model, he continued, is quite diverse depending on the product. FisTx 360 helps farmers with consultation and farm management sessions during one cycle, from preparation until harvest arrives. This product adheres to a subscription model for all cultivations both from aqua input to technology. However, the company also provides a drop-in purchase system, especially for consumers who cannot yet be reached by the field team.

Future travel

Guntur admitted that the solution developed by DELOS could theoretically be implemented not only for fish farms. In a scientific framework, from one species to another there is actually not much difference, but there are many variables and scientific assumptions that must be adjusted.

“This could all be aligned with more research, but that would be a secondary, long-term focus [for DELOS]. Our main focus is cultivating shrimp species, which is Indonesia's largest and most valuable marine commodity."

He said this because, according to the data he quoted, shrimp farming is a large but not optimal industry. The export value in Indonesia is currently in the range of $2-2,5 billion, this figure should be at least $4-5 billion per year.

"It could even be more than that if Indonesia had an aquaculture industry that could produce optimal and stable harvests, because our country has a coastline, climate and people that are hard to beat."

Rico also expressed a similar opinion. He said, basically the potential for aquaculture in Indonesia is extraordinary and FisTx wants to give the rights to each species so that it can be cultivated widely in Indonesia. "For now we are focusing on shrimp, but in the future our technology can be used on crabs, eels, lobsters and eels."

Tubagus added, reflecting on the development of a solution similar to Chickin in Israel, called Agrologic, the company developed temptron devices for pens for pigs, cows and other livestock. It is possible for Chickin to replicate it in Indonesia, because according to him, it is essentially the climate that determines the success of the harvest.

"In timeline, we now go to vertical growth acquisition from upstream to downstream, try to downstream by holding demand chicken aggregation. After that on to mid-stream (slaughterhouse), upstream (chicken coop) so we can supply farm inputs, from feed, seeds. While entering the horizontal sector outside the chicken, because we plan to do so leading meat commerce B2B in Indonesia," he concluded.

Sign up for our

newsletter

Premium

Premium